National Centre for Metal Forming and Tribology

The National Centre of Metal Forming and Tribology conducts research in all areas of metal forming processes, tribology and surface engineering with a strong focus on sheet metal materials. The centre supports the New Zealand metals industry by providing technical information and being a competent point of contact. Its expertise is available to the industry to assist in new product developments and to provide help with existing metal forming problems.

The National Centre of Metal Forming and Tribology conducts research in all areas of metal forming processes, tribology and surface engineering with a strong focus on sheet metal materials. The centre supports the New Zealand metals industry by providing technical information and being a competent point of contact. Its expertise is available to the industry to assist in new product developments and to provide help with existing metal forming problems.

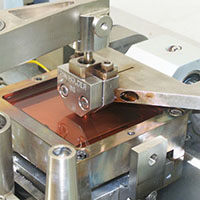

The centre is equipped with a range of state-of-the-art test instruments for tribological and mechanical characterisation. Capabilities range from evaluation for lubricants, fuels and additives to unique friction, wear and tribo-corrosion testing of advanced materials and coatings, specialised tribometers for high temperature testing as well as testing in special environments.

Facilities:

Hydraulic press

Servo-hydraulic testing machine

Block on ring tribometer

Rotary tribometer (high temperature testing up to 800°C, humidity control)

Linear reciprocating tribometer (high temperature testing up to 600°C, high frequency up to 30 Hz)

Tribo-corrosion test set-up

Scanning electron microscope

Atomic force microscope

Study with us

Selected Journal Publications

- R

amezani, M. & Schmid, S.R. (2015). Bio-based lubricants for forming of magnesium. Journal of Manufacturing Processes, 19, 112-117.

amezani, M. & Schmid, S.R. (2015). Bio-based lubricants for forming of magnesium. Journal of Manufacturing Processes, 19, 112-117. - Heinzel, H., Ramezani, M. & Neitzert, T. (2015). Experimental investigation of the formability of organic coated steel sheet metal. Procedia Manufacturing, 1, 854–865.

- Ramezani, M., Neitzert, T., Pasang, T., & Sellès, M. A. (2015). Dry sliding frictional characteristics of ZE10 and AZ80 magnesium strips under plastic deformation. Tribology International, 82(PA), 255-262.

- Ramezani, M., Pasang, T., Chen, Z., Neitzert, T. & Au, D. (2015). Evaluation of carbon diffusion in heat treatment of H13 tool steel under different atmospheric conditions. Journal of Materials Research and Technology, 4(2), 114-125.

- Ramezani, M., Neitzert, T., Pasang, T. & Selles, M.A. (2014). Characterization of friction behaviour of AZ80 and ZE10 magnesium alloys under lubricated contact condition by strip draw test. International Journal of Machine Tools and Manufacture, 85, 70-78.

- Ramezani, M., Neitzert, T., Pasang, T. & Selles, M.A. (2014). Frictional properties of AZ80 and ZE10 magnesium alloys under dry and lubricated contact conditions. Procedia Engineering, 81, 1836-1841.

- Pasang, T., Satanin, V., Ramezani, M., Waseem, M., Neitzert, T., & Kamiya, O. (2014). Formability of Magnesium Alloys AZ80 and ZE10. Key Engineering Materials, 622 - 623, 284-291.

- Ramezani, M. & Neitzert, T. (2014). Influence of humidity on creep response of sandwich beam with a viscoelastic soft core. Acta Mechanica, 225, 277-297.

- Kathirgamanathan, P., & Neitzert, T. (2014). Optimisation method of extrusion dies with a thin and complex shape. Australian Journal of Mechanical Engineering, 12(3), 317-326.

- Ramezani, M., Vilches, J. & Neitzert, T. (2013). Evaluation of the pull-out strength of galvanised steel strips in a cement-based material. Journal of Zhejiang University-SCIENCE A, 14(12), 843-855.

- Ramezani, M., Vilches, J. & Neitzert, T. (2013). Experimental and numerical analysis pull-out strength of steel strip in foam concrete. European Journal of Environmental and Civil Engineering, 17(10), 982-1001.

- Ramezani, M. & Neitzert, T. (2013). Effect of internal pressure and dent depth on strain distribution of pressurized pipe subjected to indentation. Applied Mechanics and Materials, 376, 135-139.

- Ramezani, M., Vilches, J. & Neitzert, T. (2013). Pull-out behavior of galvanized steel strip in foam concrete. International Journal of Advanced Structural Engineering, 5, 24-35.

- Ramezani, M. & Neitzert, T. (2012). A theoretical analysis for tube bulge forming using elastomer medium. Asian International Journal of Science and Technology in Production and Manufacturing Engineering (AIJSTPME), 5(4), 7-20.

- Ramezani, M. & Neitzert, T. (2012). Mechanical milling of aluminum powder using planetary ball milling process. Journal of Achievements in Materials and Manufacturing Engineering, 55(2), 790-798.

- Soomro, M.W., & Neitzert, T. (2012). Effects of temperature, strain rate and grain size on superplastic behavior of magnesium. Advanced Materials Research, 488-489, 27-34.

- Kern, F.M., & Neitzert, T. (2012). Optimization of the design of roll-formers. Transactions of the North American Manufacturing Research Institution of SME, 40, 743-749.

Staff & Students

Dr Maziar Ramezani

Mr. Mohammad Reza Arjmandi

Mr. Khashayar Khanlari

Mr. Mehdi Saeidi

Contact us

Professor Thomas Neitzert

E-mail: Thomas.neitzert@aut.ac.nz

Phone: +64 9 921 9258

School of Engineering, Computer and Mathematical Sciences, Auckland University of Technology,

34 St Paul Street

Auckland 1142